Your marketing campaign is ready to go, the packaging finalized, and your sales team is eager to hit their targets.

Everything is meticulously planned for a critical product launch when suddenly, your key supplier encounters a financial crisis and can’t deliver the necessary materials in time.

It’s a common scenario that highlights the importance of managing supplier risks. A structured approach to supplier risk management can prevent these issues by identifying early warning signs and developing mitigation strategies.

In this article, we’ll explore best practices, frameworks, and supplier management software to help you navigate these challenges.

Understanding Supplier Risks

Outsourcing key elements of your production process is risky, but understanding the different supplier risks can help you plan for the worst. Potential supplier risks include:

- Financial: This involves the financial stability of your suppliers. If a supplier is facing bankruptcy, cash flow issues, or credit downgrades, they might fail to meet their commitments, disrupting your supply chain.

- Operational: These are risks related to the internal processes of your suppliers. Issues like production delays, quality control failures, or capacity constraints can affect your operations.

- Geopolitical: Political instability, trade disputes, or regulatory changes in a supplier’s country can impact their ability to deliver goods or services.

- Environmental: Suppliers operating in areas prone to natural disasters or with poor environmental practices can face disruptions that affect your supply chain.

- Legal: Suppliers must comply with laws and regulations. Non-compliance, such as violating labor laws or environmental regulations, can lead to legal issues and disruptions in the supply chain.

- Reputational: The actions or reputation of your suppliers can impact your brand. Poor practices, such as unethical labor practices or involvement in scandals, can damage your company’s reputation.

Along with risk analysis, identifying which suppliers are critical to your operations is essential for business continuity and resilience. Consider these factors:

- Assess uniqueness: Examine the uniqueness of the goods or services provided by each supplier. Suppliers offering specialized products or services that are integral to your business processes are likely critical.

- Evaluate market position: Examine the supplier’s market position and reliability. Consider factors such as their reputation in the industry, customer reviews, and any certifications or awards they have received.

- Analyze switching costs: Evaluate the cost and feasibility of switching to alternative suppliers in emergencies. Assess any potential disruptions or quality issues that may arise during the transition period.

Assessing which suppliers are critical and analyzing how their issues could impact production helps businesses stay ahead of potential issues.

Framework for Supplier Risk Management

Businesses can manage supplier risk more effectively when they have the right policies, processes, and strategies in place.

Supplier Risk Management Policy

Having a formal supplier risk management policy helps businesses navigate potential challenges more easily. Here are a few key factors to include in your policy:

- Scope: Helps ensure that all relevant aspects of supplier risk are addressed, including financial stability, quality control, compliance, environmental sustainability, and geopolitical factors.

- Objectives: Establishes clear goals for the supplier risk management efforts, guiding decision-making and resource allocation. Objectives can include minimizing disruptions, reducing costs, or improving overall business resilience.

- Roles and responsibilities: Assigns tasks to relevant individuals or departments, clarifying who is responsible for what. For example, procurement managers might oversee supplier evaluations while compliance officers monitor regulatory requirements.

Supplier Risk Assessment Process

A supplier risk assessment is a systematic process to guide organizations through risk identification and mitigation. It can be broken down into three key steps:

- Identification: Identify potential risks by reviewing supplier information, historical data, industry trends, and external factors. Consider each of the risks outlined in the previous section.

- Analysis: Analyze each risk to understand its potential impact on your business and the likelihood of occurrence. This step involves gathering relevant data, assessing vulnerabilities, and evaluating the severity of potential consequences.

- Evaluation: Evaluate the likelihood and potential impact of each risk. Prioritize risks based on their severity and the level of control you hold. This process can help you quickly delegate resources to high-priority risks that pose the greatest threat to your business.

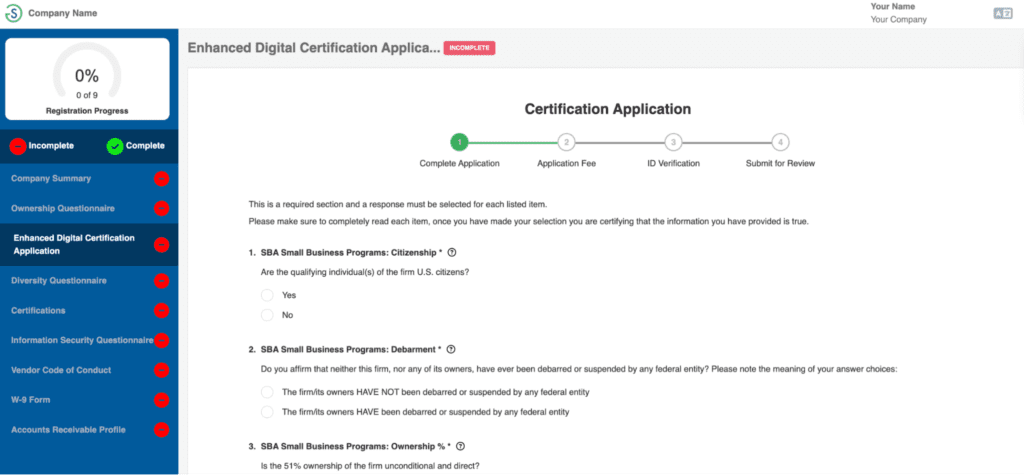

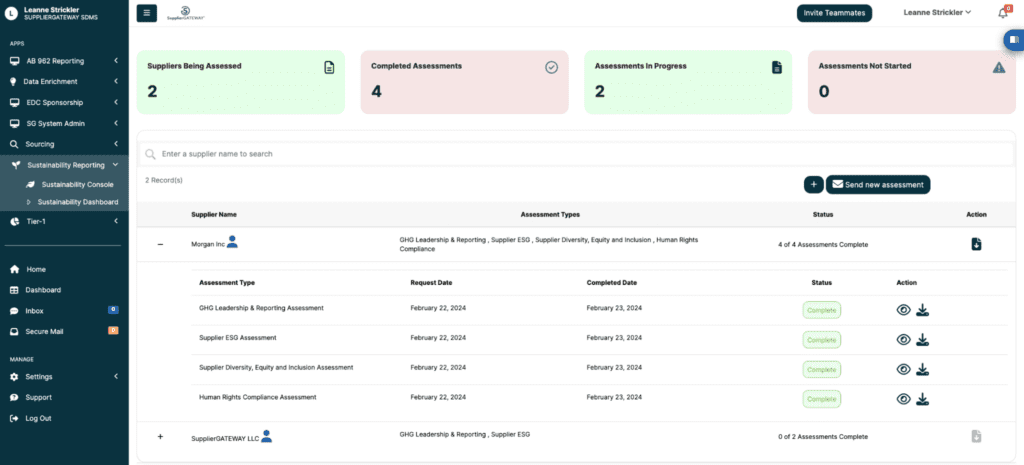

Build confidence in your supplier inventory and keep on top of risks with comprehensive sustainability assessments.

Simple, comprehensive supplier assessments.

Supplier’s assessments gather data across all environmental, social and governance (ESG), diversity, equity, and inclusion (DEI), and human rights metrics to ensure your vendors’ practices don’t affect your production.

Mitigation Strategies

Risk mitigation is a proactive approach. To avoid time-consuming and costly supplier issues, consider implementing these strategies:

- Establish backup suppliers: Identify and qualify alternative suppliers to reduce dependence on a single source. Having backup suppliers ensures continuity of supply in case of disruptions.

- Create joint risk management plans: Collaborate with key suppliers to develop risk management plans that address shared vulnerabilities and outline proactive measures to mitigate risks. This fosters stronger partnerships and enhances supply chain resilience.

- Incorporate risk considerations into procurement: Integrate risk assessment criteria into the supplier selection process to evaluate suppliers’ ability to manage risks effectively.

Investing in supplier risk management software can streamline the implementation of these strategies. Search for new diverse suppliers with certifications, work with current suppliers to reduce risk, and use critical factors to select new suppliers with our intuitive dashboard.

5 Best Practices in Supplier Risk Management

Risk management is critical and yet the most overlooked. When it comes down to supplier risk management best practices, there are five key practices for effective supplier risk management you should be aware of.

1. Centralized Supplier Database

Maintaining a centralized database helps organizations track, monitor, and analyze supplier risk. Manual tracking, assessments, and documentation is highly impractical. Having all supplier data in one place allows for easy tracking of supplier performance, compliance status, and risk exposure over time.

Enterprise supplier master data management allows you to manage the entire supplier lifecycle in one cloud-based platform. With a centralized database, businesses can also monitor changes in supplier risk factors in real-time, enabling timely intervention and risk mitigation.

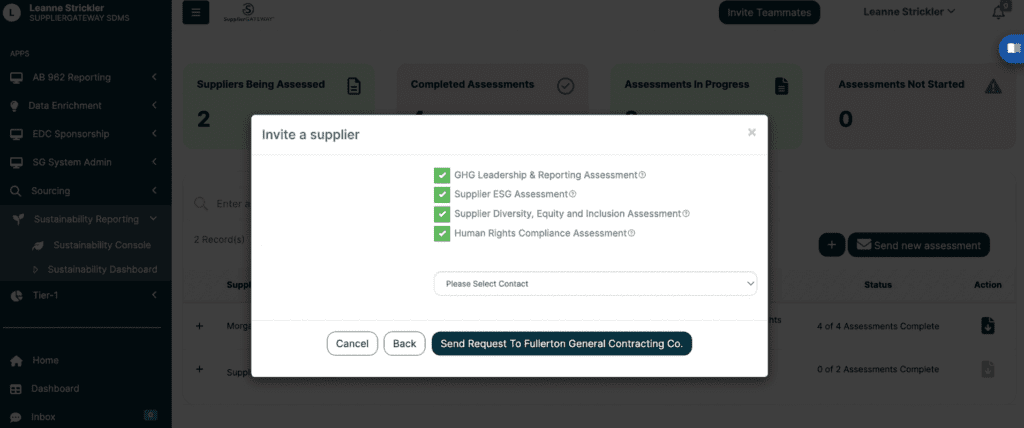

Deploy assessments to suppliers with a single click.

Conducting a comprehensive analysis and identifying patterns in supplier-related risks is also much easier with consolidated supplier information. For example, a centralized database allows organizations to track supplier compliance with ethical sourcing standards and identify potential labor or environmental risks.

2. Strategic Supplier Diversification

Diversifying the supplier base is a smart strategy to reduce dependency on any single source and mitigate risks associated with supplier concentration.

Reduced dependency on a single supplier means that if one supplier faces disruptions, your production processes remain unaffected. This strategy is especially critical for suppliers who provide essential goods and services for your supply chain.

A diversified supplier base also allows businesses to adapt to sudden changes in market conditions. Increased flexibility is the key to staying agile and responsive to fluctuations in consumer demand or supply chain disruptions.

Multiple options also gives you better negotiating power. With multiple suppliers competing for business, companies gain leverage to negotiate better terms, pricing, and quality standards.

3. Due Diligence and Ongoing Performance Monitoring

Supplier reliability depends on thorough due diligence in the supplier selection process and continuous monitoring. These processes ensure that suppliers are vetted for potential risks and that their performance stays in line with quality standards to prevent issues.

Integrating performance metrics into regular supplier reviews allows for early detection of potential issues. Prevent any potential slip ups and missed red flags with supply chain sustainability and compliance software.

With our platform, deploy supplier assessments in an instant and receive the results in as little as three weeks. Regularly audited and updated assessments guarantee that your suppliers are following ever-changing sustainability regulations.

Assessment tracking in the dashboard.

Continuous performance monitoring ensures that suppliers consistently meet agreed upon standards, such as product quality and diversity certification.

4. Contractual Risk Mitigation

Contracts play a crucial role in managing supplier risk, providing a legal framework to ensure accountability and performance. A solid contract will include several clauses to ensure suppliers follow through on the agreed upon conditions:

- Quality control clauses: establish clear expectations regarding the quality of goods or services provided by suppliers to maintain consistency and reliability.

- Compliance requirements: ensure that suppliers adhere to relevant laws, regulations, and industry standards to mitigate legal and regulatory risks.

- Remedies for non-performance: address situations where suppliers fail to meet contractual obligations to create a legal recourse in case of delays, defects, or breaches of contract.

Our supplier onboarding software streamlines contract management because it integrates with your company’s systems. This makes supplier information accessible across your entire organization — whether your legal team needs to access compliance information or the logistics department is looking for a lost shipment.

5. Collaboration and Relationship Management

Collaboration and relationship management with suppliers facilitate effective risk management. Regular engagement with suppliers allows businesses to proactively address potential issues and find mutually beneficial solutions.

When companies fail to emphasize vendor relationship management, it can lead to breakdowns in communication, misunderstandings, and conflicts. This can result in delays, quality issues, and ultimately, damage to the business’s reputation and bottom line.

Building strong relationships with suppliers fosters trust, communication, and collaboration. Not only is this critical for smooth production processes but it also helps you work together to identify, assess, and prevent risks.

How Technology Can Streamline Supplier Risk Management

The cloud, automation, and data enrichment are buzzwords for a reason. Technology (or the lack of) can make or break your supplier risk management processes.

It’s time to leave disconnected systems and spreadsheets behind and employ impactful, collaborative software to transform your supplier risk management strategy. SupplierGateway delivers with:

- Centralized data: create a single source of truth for seamless operations across your entire company, eliminating scattered information and manual tasks.

- User-friendly interface: simple, streamlined, easy to use — no steep learning curve or integration struggles here.

- Streamlined onboarding and offboarding: from onboarding to compliance documentation to proper offboarding, you control the entire supplier relationship cycle in one platform.

- Key Performance Indicators (KPIs): represent KPIs with visuals and straightforward scores to engage suppliers and drive real change in your supply chain.

- Fast and scalable compliance: send out assessments, track progress, and collaborate on action plans for all of your suppliers in one dashboard.