What Is Supplier Onboarding?

Supplier Onboarding 101: A Beginner’s Guide

Your company has decided to implement a formal supplier onboarding program at your company. This decision is about to make your life as a procurement professional a whole lot easier, but it does come along with some setup. Onboarding your vendors and suppliers the right way is key to building successful, long-term relationships.

But where do you start?

Supplier onboarding can seem complicated, but it doesn’t have to be. This guide will walk you through the basics and help you get your program up and running quickly. We’ll cover goal-setting, creating a timeline, and common supplier onboarding roadblocks. With some guidance and practice, you’ll be onboarding suppliers like a pro and wondering why your company didn’t do this sooner. The benefits are huge and the effort is worth it.

Let’s get started!

What Is Supplier Onboarding?

To put it simply, supplier (or vendor) onboarding is the process of collecting necessary information from suppliers to set them up as approved entities to purchase from. Onboarding suppliers at the start of your relationship with them also helps your company build stronger relationships with your vendors right from the start.

What exactly does supplier onboarding involve? Essentially, it’s registering new suppliers into your procurement system and making sure they meet your company’s standards. You’ll collect information from potential suppliers like business licenses, insurance certificates, product details, and compliance documents. You’ll also evaluate things like their quality, delivery, and customer service to ensure they’re a good fit.

The benefits of solid supplier onboarding are huge. It helps you:

- Find the best vendors who share your values

- Gain visibility into who you’re buying from

- Reduce risk by verifying suppliers meet requirements

- Build partnerships with vendors who get your business needs

Onboarding new suppliers does take time and effort, but it’s worth it. Following a streamlined process will make things easier for both you and your new partners. Be open, honest, and willing to help vendors through the steps. Communicate with suppliers regularly throughout the process in case any issues come up.

With the right strategy and tools (cough SupplierGATEWAY cough), you’ll be onboarding new suppliers quickly. Focus on creating a great experience for vendors, and you’ll build the foundation for long-lasting, mutually beneficial relationships. Onboarding is an investment that will pay off through better, more reliable suppliers and smoother purchasing.

Why Is Supplier Onboarding Important?

Supplier onboarding is crucial for any procurement team. Why is it so important? A few key reasons:

- It ensures compliance. Both internal policies and external regulations require proper vetting of suppliers. Onboarding helps you review suppliers against company standards, laws, and regulations.

- It reduces maverick spending. With a streamlined onboarding process, employees are more likely to choose approved suppliers that meet preferred qualifications. This avoids off-contract or non-compliant expenditures.

- It improves the supplier experience. A strategic onboarding program communicates your key expectations and makes the supplier relationship process smooth from the start. Suppliers feel valued and are better equipped to meet your needs.

- It drives cost savings. Approved suppliers that fully understand your requirements and standards often provide more competitive pricing and higher quality service. Onboarding also weeds out suppliers that can’t meet your criteria.

In summary, supplier onboarding should be a top priority for procurement pros. While it does require time and resources to implement, the benefits to your company’s bottom line, compliance, and supplier relationships make it well worth the effort. Onboarding suppliers correctly from the start creates a foundation for long-term success.

So take it step by step. Review your current processes, set clear goals, and choose an onboarding solution that fits your needs. Before you know it, you’ll have a program that transforms how you work with suppliers for the better. The results will speak for themselves!

Steps to Developing a Supplier Onboarding Program

Developing a solid supplier onboarding program takes time and effort, but the payoff—seamless integration of valued partners—is well worth it. Here are the basic steps to build your program:

Establish Clear Goals and Metrics

First, determine what you want to achieve with your onboarding program. Things like reducing risk, decreasing time to value, and improving supplier performance are common goals. Then establish key performance indicators (KPIs) to measure success, e.g. supplier compliance, cost savings, and quality metrics.

Design the Onboarding Process

Map out the end-to-end process for onboarding new suppliers, including:

- Supplier evaluation and selection: Develop standardized criteria to assess potential new suppliers.

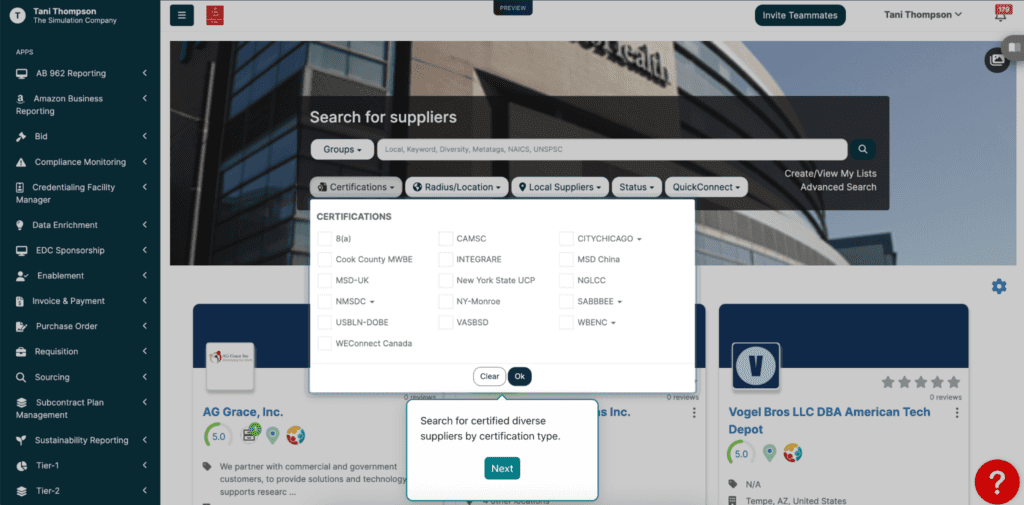

- Supplier registration: Create an online portal where new suppliers can register their information. Collect essential details like contact info, capabilities, certifications, etc.

- Contracting: Establish templates for standard paperwork like NDAs, MSAs, and SOWs. Define an efficient workflow for legal review and approval.

- Supplier kickoff: Schedule an initial meeting to introduce the new supplier relationship, share key contacts and processes, align expectations, and address any questions.

- Performance monitoring: Regularly track supplier KPIs and compliance. Provide feedback and take corrective actions as needed.

- Continuous improvement: Solicit regular feedback from suppliers and internal stakeholders. Look for ways to optimize the onboarding program and strengthen supplier partnerships.

For a more in-depth article on the supplier onboarding process and best practices, see this article.

Deploy Supplier Onboarding Technology and Other Tools

The right technology can help streamline your onboarding efforts. A supplier portal, source-to-pay system, and contract lifecycle management platform are all helpful in managing various end-to-end processes.

Investing the time upfront to build a comprehensive supplier onboarding program will lead to higher-quality supplier relationships and better business outcomes. With the proper goals, metrics, processes, and tools in place, you’ll easily onboard new suppliers.

Tools and Resources to Streamline the Supplier Onboarding Process

Once you have defined your supplier onboarding program, you will need tools and resources to streamline the process. Using a central supplier portal and onboarding platform helps ensure consistency and provides an audit trail of all communication and documentation.

Supplier Onboarding Portal

A single online portal dedicated to supplier onboarding provides a flexible, automated solution that’s available on demand. Suppliers can log in to access and submit all necessary paperwork, certifications, and information in one place. For procurement teams, portals offer:

- A central communication hub to send messages, deadlines, and updates to suppliers

- Storage for all supplier documents, contracts, and compliance records

- Configurable, automated workflows to guide suppliers through your onboarding steps

- Reporting and analytics on supplier onboarding metrics and KPIs

Standardized Templates

Provide suppliers with standardized templates based on category type. Standard information like compliance questionnaires, product data sheets, or service agreements will differ depending on supplier type. Ensure you’re getting the correct information from the correct supplier. Segmenting in this way ensures you get the details you need in a consistent format while making the process faster and easier for suppliers to complete. You can then store finalized templates in your portal.

Collaboration Tools

Tools like shared drives, project management software, and video conferencing platforms facilitate collaboration during onboarding. Your supplier onboarding portal should allow for document sharing, but having another cloud-based file-sharing system to share draft documents, schedules, and other work-in-progress materials is helpful. Video calls are useful for remote suppliers or complex onboarding scenarios.

Learning Resources

Develop resources to educate suppliers on your organization’s processes, values, and best practices. These may include guidelines, video tutorials, checklists, or FAQ documents. Making this information easily available in your portal helps suppliers understand your requirements and what they need to do to get onboarded efficiently.

With the right tools and resources in place, you’ll find supplier onboarding becomes a streamlined, scalable process. Suppliers will have a positive experience from the start, and your team will gain significant time savings and improved oversight.

Common Challenges With Supplier Onboarding and How to Overcome Them

Supplier onboarding can be tedious and time-consuming if not approached strategically. Here are some of the most common challenges companies face when onboarding new suppliers and how to overcome them:

Speed

Onboarding suppliers manually is slow and inefficient. Develop guidelines and technical specs to speed up the process. Use supplier onboarding software like SupplierGATEWAY’s Supplier Onboarding Platform to increase your onboarding speed.

Visibility

Without a standardized process, you lose visibility into where suppliers are in the onboarding journey. Create a checklist of required forms, approvals, and next steps to keep everything on track.

Compliance

Meeting regulatory and compliance standards is difficult without clearly documented processes. Define compliance requirements upfront and include review checkpoints to ensure all criteria are met before final approval.

Handoffs

Unnecessary handoffs between teams lead to stalled progress. Designate a primary contact for suppliers to prevent confusion and keep the lines of communication open.

Relationships

Building solid relationships with new suppliers takes time and effort. Schedule calls or in-person meetings to connect, address concerns, and convey your company’s values and priorities. Making a good first impression will set the foundation for a lasting partnership.

Onboarding suppliers may never be the most exciting task, but approaching it strategically with the right tools and processes can help you overcome common challenges. Focusing on speed, visibility, compliance, communication, and relationship-building will ensure a smooth transition so you can start reaping the benefits of your new supplier partnership.

Conclusion

You now have the basics to get started with your supplier onboarding program. By focusing on the fundamentals, setting clear goals, and choosing the right tools and technologies, you’ll collaborate with new suppliers in no time.

Remember, start small and build from there. Trying to onboard every supplier at once is overwhelming, so take your time to get the process right and make improvements. Supplier onboarding, like any new initiative, takes practice. Stay flexible, get feedback, and make changes as needed.

With the right mindset and approach, you’ll have a world-class program up and running before you know it. When you’re ready to take your supplier onboarding to the next level, schedule a demo and find out how SupplierGATEWAY can help!

Enable a Data-Driven Supplier Diversity Program

Supplier Diversity Data Management: The Foundation of a Successful Supplier Diversity Program

You know that a diverse supplier base is crucial for the growth of your business. You also know that launching a supplier diversity program is challenging when you don’t have a solid data foundation in place.

Your company probably doesn’t have accurate supplier information, let alone the supplier diversity information necessary to correctly track what you spend with diverse companies. Setting goals for increasing diversity spending becomes near impossible when you have no benchmark to work from.

Finding and onboarding diverse suppliers is a massive undertaking if you don’t have a comprehensive database to source from. Accurately tracking your program’s progress isn’t possible if you aren’t capturing key supplier diversity metrics from the start.

Supplier diversity data management is the key to building a successful supplier diversity program. When accurate data collection is a priority, your organization can source new vendors, track goals, identify opportunities for improvement, and ultimately achieve a diverse supply chain that fuels your company’s success.

With a data-first approach, you can transform your supplier diversity program from a good intention into a strategic advantage for your company.

Establishing the Vision and Goals for Your Supplier Diversity Program

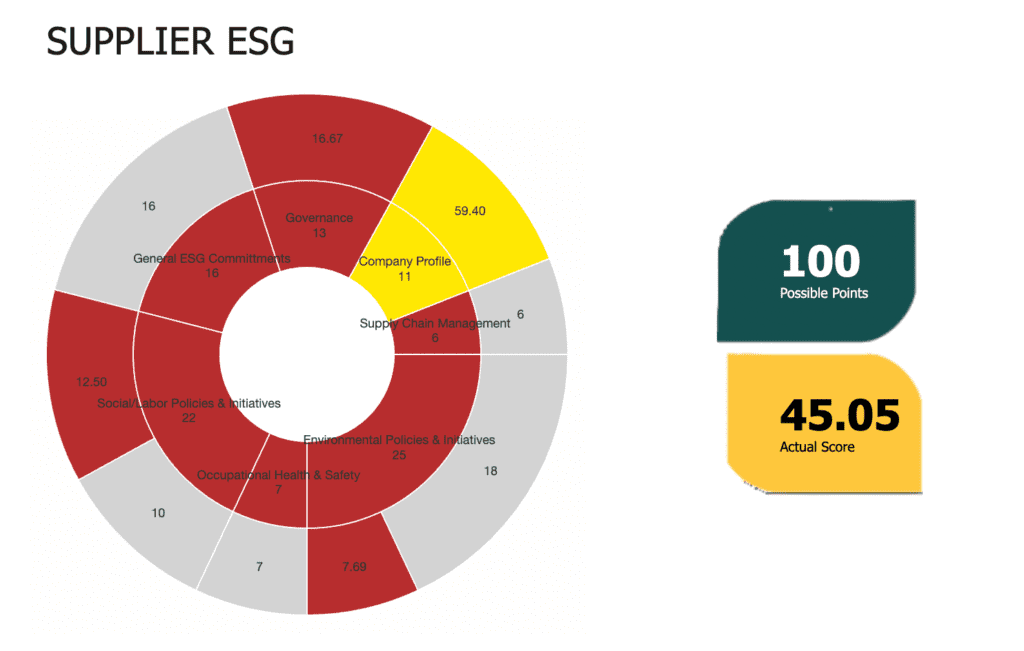

Building a successful supplier diversity program requires solid foundational supplier data and a clear vision for your program’s growth. This vision needs to include measurable goals and KPIs.

Here are some considerations to keep in mind when establishing your goals and KPIs for your supplier diversity program:

- Define what success looks like for your program. Do you want to increase spend with diverse suppliers by 5% year over year? Improve supplier retention rates? Set quantifiable and concrete targets.

- Get buy-in from leadership and key stakeholders. Explain the business case for supplier diversity and how it aligns with company values. Ask for input on goals and ways they can support the program.

- Determine how you’ll track and report on progress. Look at metrics like the number of diverse suppliers included in RFPs and bids, the percentage of spend with diverse suppliers, the number of diverse suppliers you work with, and supplier retention rates. Set up dashboards, reports, and reviews to share updates with stakeholders and make adjustments as needed.

- Map out an onboarding process. How will you find and attract new, diverse suppliers? Work with procurement to streamline the onboarding process. Automate what you can to make the experience easy for suppliers.

- Clean up your data. Enriching your current supplier data can help you find diverse suppliers that you already work with. Data enrichment also helps verify other supplier information like classifications, certifications, and contact info. The more accurate your data, the more effectively you can match diverse suppliers to opportunities.

Getting stakeholder support becomes easier when progress is measurable and goals are clearly defined. By prioritizing an efficient onboarding process and high-quality supplier data, you’ll create the foundation for a best-in-class supplier diversity program. That means growth and success for your diverse suppliers and your company.

Implementing a Supplier Onboarding Process

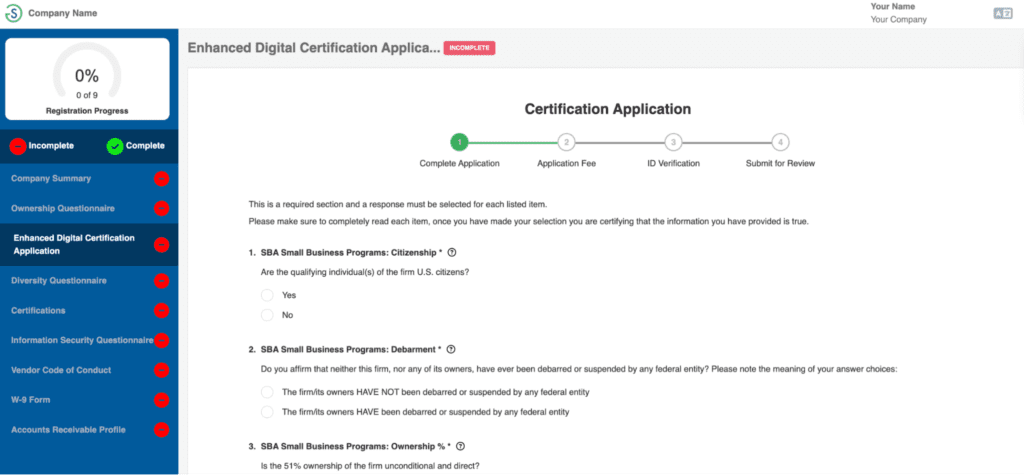

To build a solid data foundation for your supplier diversity program, you need a streamlined supplier onboarding process. Here are the key steps to implement:

- Create a supplier application that captures critical details about the supplier and their business. Contact information, certifications, products/services, and capabilities should be collected during onboarding. The more data you collect upfront, the better. To make this process as easy as possible for both you and your potential supplier, your company should utilize a self-service supplier registration and onboarding portal.

- Require suppliers to provide supporting documentation to verify certifications and classifications. This ensures you have accurate records of a supplier’s diversity status, small business designations, and more.

- Conduct a risk assessment for each new supplier. Review financials, insurance coverage, quality certifications, safety records, and anything else critical to your supply chain. Identify any red flags early on.

- Meet with suppliers either in-person or via video conference. This is your chance to clarify any details about their application, discuss the supplier’s capabilities and fit, and determine if they meet your sourcing needs.

- Once approved, officially onboard the new supplier by entering their data into your supplier management system. This centralizes all the information gathered during the application and assessment process, enabling easy reporting and monitoring of your diverse supplier base.

By implementing a comprehensive supplier onboarding process, you establish a single source of truth for your supplier diversity program. Accurate and up-to-date data on your diverse suppliers means you can match opportunities, track spend, report metrics, and ultimately achieve your program goals. With the right technology and procedures, you’ll be on your way to data-driven success.

Supplier Diversity Data Management

Successful supplier diversity programs are built on accurate, up-to-date supplier data. Collecting and managing this data should be an ongoing process. Allowing suppliers to update and maintain a supplier profile within your system is the easiest way to ensure your supplier data is always accurate.

Data Accuracy Starts with Supplier Onboarding

When onboarding new diverse suppliers, gather important details about their business, certifications, and ownership via your supplier onboarding portal. Ask suppliers to self-report information like:

- Business name, address, and contact info

- Ownership details, including gender, ethnicity, veteran status, disability status, etc.

- Certifying agency and certification expiration date

- Products, services, and capabilities

- Annual revenue and number of employees

This data should be stored in a supplier profile, which your suppliers can access and update whenever they need to via your supplier portal.

Conduct Regular Data Reviews and Updates

Invite your suppliers to update their profiles regularly. Supplier information changes regularly, so double check:

- Ownership and control of the business haven’t changed hands. If a small, woman-owned business was acquired by a large corporation, its status will change in your system and this can affect future diversity spend.

- Certifications are still valid and up to date. Most third-party diversity certifications require yearly renewals. If your business only accepts third-party diversity certifications, you need to ensure that all diversity certifications are accurate and up-to-date to count towards your diversity spend.

- Revenue, employee numbers, products, and services offered remain the same or have expanded

Report and Analyze Supplier Diversity Program Data

The data you collect is only valuable if you put it to use. Regularly report metrics like:

- Number of diverse suppliers

- Diverse supplier spend and percentage of total spend

- Growth in diverse supplier utilization over time

Analyze the data to identify opportunities to improve your program, such as sourcing products or services from underrepresented groups. Share data and insights with stakeholders to demonstrate the impact and value of your supplier diversity initiatives.

Managing high-quality supplier diversity data is essential. By collecting detailed information, conducting ongoing data updates, and reporting metrics and insights, you build a foundation for a strong supplier diversity program.

Accurate data leads to better decision-making, goal-setting, and program growth.

Using Data to Drive Continuous Improvement

Once you have a solid foundation of supplier data in place, it’s time to put that data to work. Using data analytics, you can gain valuable insights into your supplier diversity program and make continuous improvements.

Review Spend Reports

Dig into your spend reports to see how much you’re truly spending with diverse suppliers. Look for opportunities to increase spend in certain categories or with underutilized groups. Set specific percentage targets and put plans in place to achieve them.

Identify Top Performers

Use your supplier scorecards and ratings to determine your top-performing diverse suppliers. These suppliers may be good candidates for expanded business opportunities or mentorship programs with smaller diverse suppliers. Reward them for their excellent work to keep them engaged in your program.

Address Poor Performers

Your data can also reveal suppliers that are underperforming or not meeting your standards. Work with these suppliers to determine the issues and find solutions to improve. Provide resources and guidance to help build their capacity.

Refine Your Program

Look for patterns in your data that indicate certain aspects of your program could use refinement or improvement. You may find opportunities to enhance your supplier certification process, strengthen matchmaking events, expand education and training, or make your portal more user-friendly. Seek feedback from suppliers and internal stakeholders as well.

Continuously monitoring and analyzing your supplier diversity data will help ensure your program remains robust, impactful, and achievable. While using a data-driven approach requires more effort upfront, it is the key to long-term success. With the right data and tools in place, you can build a best-in-class program that drives real results.

Tips on Creating an Impactful Supplier Diversity Program

Start with the Data

To build an impactful supplier diversity program, you need to begin with solid supplier diversity data. Collect information from potential diverse suppliers through a supplier registration and pre-qualification process. Have them provide details on their certifications, capabilities, and capacity.

Streamline the Onboarding Process

Make it easy for diverse suppliers to do business with you by simplifying your onboarding process. An automated system where suppliers can enter information one time cuts down on duplicate data entry and frustration. Suppliers will appreciate how user-friendly and efficient your program is.

Promote Your Program

Spread the word about your supplier diversity program to attract qualified, certified diverse suppliers. Post on your company website, share on social media and promote at diverse business events. Let suppliers know you value building mutually beneficial, long-term relationships.

Provide Resources and Support

Offer resources and support to help diverse suppliers strengthen their businesses. This could include networking events, matchmaking opportunities, mentoring programs, and educational resources on topics like accessing capital, developing strategic plans, and improving operations. Your support and guidance can help diverse suppliers achieve stability and growth.

Measure and Report on Economic Impact

Track how much you spend with diverse suppliers, and measure how your spending impacts the surrounding community. Report these metrics to demonstrate the success of your program to stakeholders and the public. Make data-driven decisions on how to improve and expand your program over time based on the results.

Creating a truly impactful supplier diversity program requires work, but by starting with data, streamlining processes, promoting your program, offering resources, and measuring results, you can build a program that benefits both your company and diverse suppliers. Supplier diversity enriches supply chains, spurs innovation, and strengthens economic growth.

Conclusion

By focusing on the fundamentals of supplier diversity data management, you can build a solid foundation for your supplier diversity program. Streamlining the supplier onboarding process ensures you have accurate and complete data on your diverse suppliers and the ability to report engagement and spend accurately.

Now you can start reaping the benefits of a data-driven program. Armed with insights into your program’s performance, you can demonstrate the impact and value of the supplier diversity program to stakeholders, your customers, and your community.

When you’re ready to enable a data-driven supplier diversity program, get in touch and one of our experts will show you how.

Supplier Onboarding and Offboarding for Commercial Real Estate Developers

You know how important it is to find suppliers for your commercial real estate projects. But did you also know that correctly onboarding and offboarding those suppliers can make or break the success of your projects?

As a procurement pro in the real estate world, you deal with constantly moving parts, and suppliers are a huge part of keeping all those parts running smoothly. You know you have to be strategic about bringing on new suppliers and ending relationships with those that no longer suit your needs.

This guide will walk you through best practices for onboarding new suppliers and includes tips for offboarding suppliers at the end of a project. Following these recommendations will help you build better relationships with suppliers, avoid costly mistakes, and gain efficiencies that boost your bottom line. Read on to learn how to master the art of supplier onboarding and offboarding.

The Benefits of Effective Commercial Real Estate Supplier Onboarding

As a commercial real estate developer, effective supplier onboarding should be a top priority for your procurement team. There are many benefits to having a strong supplier onboarding program:

- Faster time to value. With an efficient onboarding process, your new suppliers can deliver value immediately. No more waiting weeks or months while they try to figure things out.

- Improved compliance. A good onboarding program and platform help ensure suppliers meet all your compliance requirements from the start. You can capture compliance information, like insurance certificates, quality certifications, and data privacy standards up-front instead of rushing to get them later.

- Reduced risk. Onboarding suppliers thoroughly helps avoid issues like delayed projects, poor work quality, data breaches, and fraud. You’ll have confidence in your supplier’s abilities and trust in the partnership.

- Cost savings. An optimized onboarding process saves your team time and money. No more chasing down supplier information or fixing data entry mistakes. This helps suppliers hit the ground running, which helps projects stay on budget.

- Stronger relationships. Taking the time to properly onboard suppliers shows you value them and the partnership. This goodwill fosters collaboration and a shared commitment to success. Suppliers will appreciate your professionalism and be motivated to deliver.

The benefits of effective supplier onboarding for commercial real estate developers are clear. With the right process and technology, you can onboard suppliers faster, ensure compliance, reduce risk, cut costs, and build better partnerships. Now that’s a solid foundation for success.

Steps to Streamline Your Commercial Real Estate Supplier Onboarding Process

Streamlining your supplier onboarding process is key to saving time and money. With tools like SupplierGATEWAY’s Supplier Onboarding and Offboarding Platform, you can onboard new suppliers up to 700 times faster.

Following the suggestions below will help you to further reduce the time and cost involved with onboarding new suppliers:

- Automate as much as possible. Use a supplier onboarding and offboarding platform that allows suppliers to self-serve by entering information directly into online forms. This eliminates the need for manual data entry for you and reduces errors since the supplier fills in the information themselves.

- Make information easy to find. Have a centralized repository for all supplier documentation, contracts, insurance information, and communication. Your team and suppliers should be able to access everything in one place.

- Standardize your processes. Create templates and workflows for repeatable forms and contracts. Checklists and workflows in your onboarding platform guide suppliers through the required steps and ensure all forms are complete.

With automated tools, standardized processes, and a centralized repository, you’ll be onboarding new suppliers faster than ever. When it’s time to offboard, you’ll have a system in place. When you streamline supplier onboarding and offboarding, your procurement team and bottom line will reap the benefits.

Managing Supplier Relationships and Performance

Once you have onboarded your suppliers, the real work begins—managing supplier relationships and ensuring strong supplier performance. As a commercial real estate developer, staying on top of suppliers is critical to keeping your projects running smoothly and on budget.

Here are the basics for managing your supplier relationships:

Communicate Regularly

Make time for consistent calls, emails, and in-person meetings with key suppliers. Discuss current projects, potential issues, and ways to improve the working relationship. Listen to any concerns the suppliers may have and address them promptly. Open communication and quick response times build trust and help avoid surprises later on.

Conduct Performance Reviews

Reviews of key suppliers should be conducted annually at a minimum. These reviews evaluate their performance, quality, responsiveness, and value. Compare actual performance to the agreed upon contract or service level agreement. Discuss positives and opportunities for improvement, setting clear expectations for the next review period. Consider putting suppliers on a performance improvement plan or terminating the relationship if performance does not improve.

Provide Feedback

Don’t just evaluate suppliers—give them constructive feedback they can act on. Explain what they’re doing well and how they can improve. Ask for their input on how your organization can improve the working relationship as well. Continuous feedback and a willingness to listen on both sides will strengthen partnerships in the long run.

Resolve Issues

Despite best efforts, problems can still arise. Develop a clear issue resolution process, including escalation steps, to address issues quickly and minimize impact. Be proactive by anticipating potential issues before they occur. Discuss possible scenarios and solutions with suppliers to build alignment on the appropriate path forward in the event of a problem.

Maintaining open communication, conducting regular reviews, providing constructive feedback, and having a solid issue-resolution process will help ensure successful long-term relationships with your suppliers. Strong supplier management is essential for keeping your real estate development projects on track.

Best Practices for Commercial Real Estate Supplier Offboarding

When it’s time to part ways with a supplier, you need an easy way to terminate contracts, disable system access, and archive records. Offboarding checklists provide a structured process for a clean break.

Have a Transition Plan

A well-defined exit strategy for offboarding suppliers is critical for completing the supplier lifecycle properly. Work with your procurement team to determine how long the offboarding process will take and implement a comprehensive transition plan. Consider the following when offboarding suppliers:

- Will their work or services be transitioned to a new supplier or brought in-house? Ensure the transition does not affect your company’s productivity or services.

- What data, files, logins, tools, or other assets do they have access to that need to be transferred or revoked? Safeguard your company’s digital infrastructure.

- How will you handle any remaining financial obligations or payments still owed to the supplier? Tie up any loose ends.

Communicate Clearly

Once you have a transition plan, be upfront and transparent in communications with the supplier about the offboarding process and timeline. Explain the reasons for ending the relationship and provide specific details on the next steps. Be available to answer any questions they may have.

- Schedule a call or meeting to personally deliver the news if possible. Don’t just send an email.

- Share the key milestones and deadlines in the transition plan. Let them know what is expected of them and by when.

- Express appreciation for their partnership and work. Even though the relationship is ending, you want to remain professional.

Monitor Progress and Provide Feedback

As the offboarding progresses, closely monitor the supplier’s work and transition efforts. Provide feedback and guidance as needed to keep things on track. Conduct regular check-ins to identify any roadblocks or issues right away. You want the offboarding to go as smoothly as possible.

Offboarding suppliers the right way is just as important as onboarding them. Using best practices for supplier offboarding will help ensure a cleanly-ended relationship with the supplier. While ending a supplier relationship can be complicated, you can navigate it efficiently and secure your company’s interests.

Conclusion

When you invest the time to create a commercial real estate supplier onboarding and offboarding program, you set your projects up for success. Your suppliers feel valued and motivated to perform at their best, and you have confidence in their ability to deliver according to your standards and timelines.

While the processes may require effort upfront, the long-term payoff is worth it. Your projects will run more efficiently, stay on budget, and meet quality expectations. Your company will also build a reputation as a preferred client that suppliers want to work with, giving you access to the best resources and pricing.

When you prioritize supplier onboarding, management, and offboarding, you’ll quickly see the benefits to your bottom line and peace of mind. Find out how SupplierGATEWAY can help your organization with supplier onboarding and offboarding by scheduling a demo!

Supplier Offboarding Best Practices

All relationships, professional or otherwise, eventually come to an end. This includes relationships with your suppliers as well. While breakups are never fun or easy, there are strategic ways to end relationships with suppliers that can help your company reduce risk in the long run.

This is where supplier offboarding comes into play.

To put supplier offboarding into perspective, imagine you’ve decided to stop using a particular credit card altogether. The interest rate is too high, the fees are ridiculous, and using the card is more trouble than its worth. You take the card out of your wallet and throw it in the trash, but you don’t bother to destroy the card before throwing it away, and you don’t call the credit card company to close your account.

Is that how you’d go about ending a relationship with a credit card company? Not if you’re interested in protecting your financial security.

So why would ending a relationship with a supplier to your company be any different?

But this is exactly what most companies do; they simply stop buying goods or services from suppliers they no longer wish to do business with.

Just because you’ve stopped buying from a supplier does not mean that you’ve ended your relationship, and your company may still be on the hook regarding financial, legal, and other types of risk.

Because supplier offboarding is a newer concept regarding risk mitigation and management, we wanted to offer an easy-to-understand framework that will help your company establish best practices when starting a new supplier offboarding program.

What is Supplier Offboarding and How Does It Help My Company?

Supplier offboarding refers to the steps a company takes when ending a partnership with a supplier. The goal is to ensure all obligations to a supplier are fulfilled and any risks from that supplier are properly mitigated.

An effective offboarding program should cover a few key areas:

- Contracts: Review contracts and ensure your obligations are met. Make sure you are not on the hook for any supplier liabilities.

- Assets: Determine what, if any, physical assets the supplier has that belong to you. Equipment, inventory, or intellectual property are examples of assets. Make arrangements to get those back, and have a documented paper trail.

- Data: Ensure all company data is removed from supplier systems. You don’t want sensitive data lingering after the partnership ends.

- Processes: Update any internal processes, systems, and tools that involved that supplier. Remove their access and information.

- Communications: Formally communicate the end of the partnership to relevant teams and stakeholders. Make sure everyone is on the same page about the offboarding.

- Audits: Consider doing an audit of the offboarding process to ensure everything was properly completed and documented. This helps you improve future offboarding programs.

Benefits of Supplier Offboarding

When done correctly, supplier offboarding has several benefits:

- Risk management: Offboarding suppliers that pose potential risks helps protect your company from reputational damage, legal issues, and financial losses.

- Cost savings: Terminating relationships with underperforming or expensive suppliers can lead to cost savings by lowering the cost associated with managing them or by switching to more cost-effective alternatives.

- Improved supplier portfolio: Offboarding allows you to refine your supplier portfolio by focusing on high-performing and reliable suppliers. This improves the overall quality of your supply chain and helps your organization to achieve its strategic goals.

- Enhanced performance: Offboarding underperforming suppliers and replacing them with more efficient ones can lead to improved performance in terms of product quality, delivery times, and customer satisfaction.

- Better resource allocation: By offboarding suppliers that no longer meet your organization’s needs, you can redirect resources toward more strategic partnerships and initiatives that align with your business objectives.

- Continuous improvement: The offboarding process, including exit interviews and performance evaluations, can provide valuable insights into areas where your organization’s supplier management processes can be improved.

- Stronger relationships with remaining suppliers: By maintaining a smaller, more focused supplier base, you can foster stronger relationships and collaboration with your remaining suppliers, leading to better overall performance and results.

- Clear message to other suppliers: Having a supplier offboarding program communicates to suppliers that your company is committed to maintaining high standards. This can encourage them to continually improve their performance to maintain their partnership with your company.

Playing Fast and Loose: The Risks of Not Having a Supplier Offboarding Program

Setting up a supplier offboarding program will take some time, but the benefits far outweigh the time expenditure involved. Incorrectly ending relationships with suppliers opens your organization up to all sorts of risks.

Do you really want to play it fast and loose with potential litigation and financial loss?

Here’s a list of the risks your company may face should you choose to forgo a supplier offboarding program:

- Legal disputes: Failing to follow contractual obligations or adhere to termination clauses can result in legal disputes that are costly, time-consuming, and can result in reputational damage for your company.

- Financial losses: Inadequate offboarding can lead to unresolved financial matters, such as outstanding payments or refunds. This can create financial losses and strain the relationship between your organization and the supplier.

- Operational disruptions: Improperly changing over responsibilities and resources can lead to disruptions in your operations. This can affect product quality, delivery times, and overall supply chain efficiency.

- Loss of knowledge and resources: If you don’t transfer knowledge, documentation, and other resources effectively, you may lose valuable information that’s critical to your business. This can lead to delays or difficulties when onboarding new suppliers or transitioning work internally.

- Damaged reputation: Mishandling the offboarding process can damage your organization’s reputation, making it more challenging to attract and retain reliable suppliers in the future.

- Negative impact on remaining suppliers: Poorly managed offboarding sends the wrong message to other suppliers and can undermine their confidence in your organization. This can lead to poor supplier performance.

- Missed opportunities for improvement: Failing to gather feedback and insights during the offboarding process can result in missed opportunities to learn from the experience and enhance your supplier management processes.

- Strained business relationships: Poor communication and a lack of transparency during the offboarding process can strain the relationship with the departing supplier, potentially affecting future business opportunities or collaborations.

Successfully Offboard Suppliers with These 8 Best Practices

If your company wants to start a supplier offboarding program but doesn’t know where to begin, check out how to create and use a supplier offboarding checklist as a starting point.

The best practices listed below all help with making the offboarding process as easy as possible for both your company and your supplier while reducing your company’s risk exposure:

- Establish a clear offboarding policy: Develop a standardized procedure for offboarding suppliers that includes all necessary steps, from the initial decision to the final termination of the relationship. This policy should be well-documented and easily accessible to all relevant stakeholders.

- Communicate effectively: Inform the supplier of your decision to end the relationship in a timely and professional manner. Clearly explain the reasons for offboarding and provide any necessary feedback to help them understand your decision.

- Review contracts and agreements: Evaluate existing contracts and agreements to identify any termination clauses or requirements. Ensure compliance with these terms and conditions to minimize potential risks or legal disputes.

- Settle financial matters: Ensure all outstanding invoices, payments, and refunds are settled before officially terminating the relationship. This includes addressing any disputes or discrepancies in a fair and timely manner.

- Transfer knowledge and resources: If the supplier was responsible for managing specific tasks or projects, ensure a smooth transfer of knowledge and resources to your internal team or a new supplier. This may involve sharing documentation, training materials, or other relevant information.

- Conduct an exit interview: Gather feedback from the supplier regarding their experience working with your organization. This information can provide valuable insights to help improve your supplier management processes in the future.

- Update supplier records: Remove the supplier’s information from your vendor database and any other relevant systems to avoid confusion or errors in the future.

- Monitor the transition: Keep a close eye on the transition process to ensure there are no disruptions or issues during the handover to a new supplier or internal team.

SupplierGATEWAY has created a Supplier Onboarding and Offboarding Platform that helps your company effectively manage suppliers and risk throughout the entire supplier lifecycle. When you’re ready to stop fighting with spreadsheets full of incomplete and inaccurate data, request a demo and see how our supplier management solutions can save you time, money, and stress.

Healthcare Onboarding Done Right: Best Practices for Vetting and Integrating New Suppliers

Finding, onboarding, and managing healthcare suppliers can be tedious and time-consuming. But as a hospital/healthcare system buyer or procurement specialist, you know that taking shortcuts in this process can cost you time, money, and—most importantly—patient safety.

That’s why vetting and integrating new healthcare suppliers is so critical. Ensuring suppliers will provide high-quality products and services and adhere to HIPAA compliance guidelines and other regulations is paramount. Because of this, vetting and onboarding new suppliers is often tedious and time-consuming. Thankfully, there are best practices that can help you streamline your supplier onboarding process.

In this article, we’ll explore the critical steps for successfully vetting and integrating healthcare suppliers into your organization. We’ll share tips on quickly assessing a supplier’s services and capabilities so you can confidently establish goals and expectations for each partner. Let’s get going!

Develop a Strategic Sourcing Plan for New Healthcare Suppliers

The first step in vetting and onboarding new healthcare suppliers is to develop a strategic sourcing plan. This plan should include a specific set of criteria that suppliers must meet, such as:

-Compliance with regulatory standards related to the healthcare industry (e.g., Joint Commission accreditation, HIPAA compliance).

-Proof of quality and safety concerning products and services provided.

-A commitment to fair pricing agreements that represent value for the hospital/healthcare system

-The ability to provide timely and reliable delivery of goods or services.

Developing a strategic sourcing plan helps ensure all potential suppliers are held to the same high standards, so you know you’re selecting only those who can add value to your hospital system. A strategic sourcing plan also allows you to identify the features of a successful supplier relationship so that your organization can make more informed decisions when selecting new partners.

To learn more about strategic sourcing, check out these articles:

The Seven Step Strategic Sourcing Process

Multi-sourcing: Everything You Need to Know

Conducting Due Diligence: Review the Healthcare Supplier’s Credentials

Due diligence is an essential step in the onboarding process for any healthcare supplier. This is your opportunity to review the supplier’s qualifications and ensure they meet your hospital’s safety, quality, and value requirements.

Begin with a thorough review of a supplier’s credentials, including any applicable licenses and certifications. Check for compliance with state and federal regulations, such as HIPAA certification and appropriate local, state, and federal licensing. It may also be beneficial to look through reports of prior performance or customer feedback about the supplier’s products or services.

You should also review a supplier’s financial standing to ensure they are in good condition to perform their contractual duties. This review can include checking their balance sheet, income statement, and cash flow statement. Checking a supplier’s financials will help you assess their stability and help ensure they can meet their contractual obligations.

Lastly, you should check the references of previous customers who have worked with the supplier. Ask questions about product quality, delivery schedule adherence, customer service level, etc. This check helps ensure that your organization gets the best value for money from its healthcare suppliers.

Evaluating Product Quality and Safety

Another critical component of correctly onboarding healthcare suppliers is evaluating their products for quality and safety. You must have confidence in the products you purchase. This helps ensure patient satisfaction and safety and reduces the risk for your organization concerning unforeseen legal or other liability issues.

Here are some tips to help you better evaluate the product quality and safety of potential new suppliers:

- Conduct thorough product reviews: Before signing any contracts or agreements with a supplier, thoroughly review all products offered. Ensure they meet all relevant healthcare standards and regulations, and consider patient experience when reviewing products.

- Ask to see clinical results: Request product performance data from manufacturers that were generated through clinical studies or trials within healthcare environments. Doing this will provide valuable insights into the efficacy of a product before using them in real-world conditions.

- Eliminate potential risks: Assess risks associated with a new supplier before entering into a contract or purchasing any of their products. Develop protocols for analyzing potential risks, such as analyzing financial records or identifying problems with previous contracts with other customers/hospitals. Having these protocols in place will help mitigate any potential risks associated with a new supplier before being onboarded in your system.

With these best practices, you’ll be able to ensure that all onboarded suppliers meet the high standards expected by your hospital or healthcare system while eliminating potential risks associated with bringing on a new supplier relationship.

Negotiating Contracts With Healthcare Suppliers

When negotiating contracts with healthcare suppliers, keep these best practices for cost savings and risk management in mind:

Get the facts

Getting all the facts about the supplier’s reliability, quality standards, and documentation before purchasing for your healthcare system is critical. Make sure you completely understand what you’re buying, and check their references to verify their claims regarding a product or service.

Automate where possible

Automation technology can make the onboarding process much faster and more efficient while reducing risk exposure. For example, automating supplier onboarding can help ensure that all suppliers have read and agreed to abide by your hospital’s policies and procedures. The right platform will enable you to identify non-compliant suppliers quickly and take appropriate action

Use an Integrated Management System

Using an integrated management system streamlines the supplier lifecycle management process by connecting every step from onboarding to offboarding with minimum effort from your procurement department. An integrated platform like SupplierGATEWAY’s Supplier Onboarding and Offboarding Platform also provides an audit trail of all communications between suppliers and hospitals—making it easier to pinpoint any issues that arise during the contracting process.

Onboarding New Healthcare Suppliers: Training and Integration

Another factor of successful healthcare supplier onboarding is training and integration. Without properly orienting and training new suppliers on the goods and services they will be providing and the operational processes they are expected to follow, healthcare systems often struggle with ensuring that suppliers deliver products and services in compliant, secure, and standardized ways.

After training, suppliers should understand your organization’s expectations. They should also understand how your organization measures the quality of the goods/services they provide. Additionally, new suppliers should be made aware of legal risk management issues such as contract law and medical device regulation compliance.

Once the supplier has been trained on quality assurance methods, the next step is to integrate them into your organization’s infrastructure. Integrating new suppliers into existing systems reduces time spent onboarding future vendors and helps promote the long-term loyalty of your most trusted suppliers. Technology like SupplierGATEWAY’s Supplier Onboarding and Offboarding Platform streamlines this process with a self-service supplier onboarding portal that allows suppliers to enter their data directly into your system. This ensures that supplier information comes directly from the source and is consistent throughout your organization.

When The Relationship Ends: How To Offboard Suppliers and Reduce Risk

Knowing how to end relationships with suppliers is just as important as knowing how to start them. Reducing risk when it comes time to offboard suppliers is a crucial part of your healthcare system’s success and staying compliant.

So what processes should you have in place when ending a relationship with a supplier?

Audit Trail

First, establish an audit trail that includes the supplier’s performance. Make sure to include any issues that arose with the supplier. This audit trail will help with compliance and legal requirements, so keep it organized in an easy-to-access place.

Re-evaluate

Next, re-evaluate the supplier’s performance with your healthcare system. Did they deliver on their contractual obligations? Are there any processes that could be improved? Answering these questions will give you valuable insight into how successful the partnership was—and it may help establish expectations for future onboarding processes.

Check contracts

Finally, check all contracts associated with the supplier relationship and ensure that all contractual obligations have been met—or if they haven’t been, figure out why not. This way, you can be sure there are no financial or legal repercussions after offboarding them. Once you have settled all contracts, you can confidently terminate the relationship without risking any long-term issues or legal liabilities.

Using SupplierGATEWAY’s Supplier Onboarding and Offboarding Platform, those responsible for supplier onboarding and offboarding can keep track of the entire process so nothing is missed or mishandled along the way.

Conclusion

Healthcare onboarding is essential for hospitals to maintain control over their supply chain processes. It requires a comprehensive, multi-tiered approach to vetting and integrating suppliers, which needs to be tailored to each hospital’s unique needs. By having a well-structured, reliable onboarding and offboarding process in place, hospitals can avoid unexpected risks and ensure that their supply chain is compliant, secure, and cost-effective.

Ready to see what our Supplier Onboarding and Offboarding Platform can do for you? Schedule a demo with one our our experts.

A Guide for Suppliers: Understanding How Buyers Select Vendors

Have you ever wondered what buyers are looking for in a supplier? It’s a difficult thing to know, and you might feel like you’re shooting in the dark when it comes to filling out bids and submitting them to buyers.

Trying to find the perfect combination of price, delivery time, and product quality is hard enough as it is, and understanding exactly what criteria buyers want from suppliers can be challenging. Luckily, there are some key things that buyers look for in a supplier that you can use to your advantage.

In this article, I’m going to share with you the knowledge I’ve gathered from working with both buyers and suppliers during my 10+ years in the industry. My tips will help give you a better understanding of how buyers select vendors so that you can increase your chances of getting awarded contracts. Let’s get started!

How Buyers Research and Identify Potential New Suppliers

Understanding how buyers search for new vendors can help you increase your chances of being noticed. Generally, buyers use a three-step process to identify potential suppliers: research and identify vendors, assess options, and select a vendor.

When researching for new vendors, buyers want to find a supplier who fits their needs. To do this, they look at suppliers’ websites, industry directories, conversations with other buyers, digital industry events, and more. Buyers often seek out a range of price points and capabilities when starting the search process.

When assessing potential suppliers, buyers explore the supplier’s qualifications such as certifications or accreditations like ISO certification or other industry-specific certifications. They also evaluate pricing plans and customer feedback or reviews to evaluate how trustworthy the supplier is and how it has performed in the past.

Finally, when it comes time to select a vendor, buyers consider factors like customer service history as well as overall pricing structure to determine which vendor is best suited for their needs. Keep in mind that there may be competing interests at play—for instance, internal procurement requirements versus preference from end users—so what makes sense from a quality perspective may not be prioritized over cost savings considerations.

What Buyers Look for When Evaluating Suppliers: Quality, Experience, and References

When buyers are looking for suppliers, one of the most important qualities they evaluate is the quality of the products and services offered. They want to ensure that their potential vendor can meet deadlines and quality expectations, which includes agreeing to any contractual requirements. Buyers also want to ensure that any potential supplier can keep up with their demands.

In addition to quality, buyers want to work with vendors that are experts in their respective industries. Having a good reputation and positive references from current or past customers helps to reassure buyers that they are selecting a credible supplier.

Finally, buyers will always consider cost. Although price is not the only factor in selecting a supplier, buyers usually prefer vendors who offer competitive pricing without compromising quality. Ultimately, having all these elements—quality, experience, and references—in place will help your business stand out from the competition and make it easier for buyers to choose you as their partner.

The Importance of a Supplier’s Online Presence and Website

A supplier’s online presence and website also play a crucial role in the buyer’s decision process. Buyers typically look for suppliers with a website that provides detailed information about their services, products, and pricing structure. Information on a website can give buyers an idea of the supplier’s size, capabilities, and services.

Establishing trust

Having a transparent website with active customer reviews and testimonials also helps build trust with buyers. Testimonials from current or past customers can demonstrate that the supplier is reliable, trustworthy, and able to meet buyer expectations. A well-designed website helps reflect a supplier’s professionalism. A well-designed website gives buyers confidence in the supplier’s ability to produce quality products and services.

Easy access

Buyers also value websites that are easy to access and navigate. If buyers find it difficult or time-consuming to search for what they need, they may be more likely to move on to another vendor with an easier-to-navigate website. Buyers need to understand how knowledgeable and organized the supplier is, so be sure your website is clear and concise.

As a supplier, you should know that potential buyers will look at your website before making decisions. Your website sells your products and services 24/7. Ensure your online presence is professional and up-to-date to attract new customers.

How Buyers Assess the Financial Stability and Capacity of Suppliers

It’s important to understand that buyers assess the financial stability and capacity of suppliers before signing a contract. After all, buyers need to have confidence that they can trust you to deliver on your promises in the long term.

Here’s how buyers typically assess financial stability:

- Review of financial statements: Buyers often check your company’s financial records, such as profit and loss statements and balance sheets, to understand your company’s financial standing. They also check for previous outstanding debts or liabilities.

- Evaluation of past performance: Buyers like to know how well you’ve performed in the past—did you meet specific deadlines? Deliver within budget? Offer competitive rates? Were there any customer service issues? This information helps buyers evaluate whether you will be able to meet their requirements in the future.

- Analysis of market position: Buyers will look at things like your brand equity, current tariffs, market trends, and customer reviews to determine whether doing business with you is beneficial for them in the long run.

Buyers assess vendor financials and capabilities because they want to ensure that they’re entering into a contract with a financially stable supplier who has proven capable of meeting their requirements in terms of quality, timelines, and budget expectations. If a supplier can demonstrate this through their records and past performance, they’re more likely to win better contracts from buyers in the future.

The Role of Samples, Trials, and Site Visits in the Supplier Selection Process

As part of the supplier selection process, buyers often ask prospective suppliers for samples, trials, and even site visits. This is their way of getting the assurance that you can handle the job. This also ensures buyers that your products meet their needs and allows them to understand how your services are delivered.

Having a great sample to share with potential clients can make all the difference in being selected as a vendor. Buyers will judge potential suppliers on the quality of their samples, so put some extra effort into making sure they are as perfect as they can be—both in terms of content and presentation.

Trials are also used to assess whether or not you have the capabilities required for a particular project. In this situation, buyers will need to make sure that your products and services fit their needs, including if they work properly or if they comply with specific regulations or standards.

Last but not least, don’t be surprised if one of your potential clients asks for a site visit before awarding you a contract. Site visits allow buyers to evaluate your operations first-hand, from what your production looks like to how efficiently orders are processed and shipped.

Negotiating With Buyers and Winning the Contract

Diving into a contract negotiation can be intimidating, but you can give yourself an edge with these tips to ensure you increase your chances of winning the deal.

Understand the Buyer’s Needs

Start by exploring the buyer’s needs, preferences, and challenges thoroughly. It’s important to ask questions, do research and tweak your offerings accordingly. Make sure to tailor your solutions and practices to meet their requirements. Doing so will show that you ‘get it’ and are honest about what you can provide.

Be Flexible

Buyers want flexible vendors, so keep that in mind as you negotiate. Be prepared to think outside the box and consider offers that benefit both parties. Modify your services or products depending on the buyer’s wants and needs, but only do so if the contract and relationship are profitable and worthwhile.

Build Credibility

You can build credibility by providing competitive pricing, having letters of recommendation from existing customers who have been satisfied with your work, and assuring buyers that you’ll meet deadlines without fail. Being punctual in responding to emails is also essential, as it shows potential buyers that you take their business seriously — demand attention with promptness!

By understanding the buyer’s needs, remaining flexible with what you offer, and building credibility, suppliers can increase their chances of winning a lucrative contract from buyers – best of luck!

Conclusion

In conclusion, being a successful supplier takes more than fulfilling your obligations with every sale. Setting yourself up for success requires understanding how buyers look for and select new suppliers. Ensure your products fit their needs, invest in the right technology to make communication easy, build a good relationship with buyers, and demonstrate how you can benefit their bottom line. With these tips, you’ll set yourself up for success as a vendor and have buyers lining up wanting to work with you.

5 Benefits of Automating Your Supplier Onboarding Process

Vendor onboarding, the process of bringing on new vendors to your operations, can be a time-consuming and tedious task. You may have heard that it’s one of the most difficult and critical parts of supply chain management – and you’d be right! From administrative forms to due diligence reviews and compliance checks, there’s a lot to juggle when trying to bring on new vendors.

That’s why we here at SupplierGATEWAY have put together this guide: to make vendor onboarding easier. We’ll show you step-by-step how our cloud-based supplier management platform can help streamline your vendor onboarding process from start to finish. Read on for everything you need to know about getting your new vendors up and running smoothly.

What Is Vendor Onboarding?

Vendor onboarding is one of the most important steps in maintaining a successful supply chain. It’s the process of bringing a new vendor into the fold—ensuring their compliance with your company’s standards, criteria, and processes. This usually involves contracts and agreements, security measures, system integrations, training, and more.

To put it simply: think of it as being similar to your first day at a new job. You’re required to complete paperwork, learn the company’s protocols, and get up to speed on how things are done around here. Vendor onboarding walks your suppliers through this same process—allowing them to become part of your business quickly and efficiently.

So if you’re looking for a way to streamline the process of onboarding suppliers without sacrificing quality control or data protection—vendor onboarding is for you.

The Benefits of Vendor Onboarding

Vendor onboarding is a powerful tool to improve communication and collaboration between vendors and your business. With a streamlined onboarding process, you can:

- Reduce risk exposure by verifying vendor information before signing contracts.

- Quickly troubleshoot vendor performance issues by leveraging standardized processes, documents, and metrics.

- Streamline payment processes with integrated technology solutions such as digital signatures, Automated Clearing House (ACH) payments, and digital invoicing.

- Establish better relationships with vendors by providing clear and timely communication about order status, payment terms, and other critical information.

- Increase efficiency by automating tedious manual tasks such as document management, payment processing, and supplier performance tracking.

By taking the time to set up a vendor onboarding process, you’ll create healthier partnerships in the long run and save time for both you and your vendors in the short run.

Streamlining the Vendor Onboarding Process

Streamlining the vendor onboarding process can be achieved with a few simple steps. By using SupplierGATEWAY’s onboarding platform, you can easily set up custom workflows and automate each step of the process, so you don’t have to manually track and update every detail.

Here’s what streamlining your vendor onboarding process can do for you:

- Automation of the entire onboarding process into one step-by-step flow.

- Automatic updates regarding supplier status to make sure all details are accurate.

- Improves accuracy by eliminating manual data entry and manual processing of sensitive information.

- Quickly responds to supplier inquiries with detailed feedback & notifications.

- Set up customized workflows & automation.

- Automatically approve/reject suppliers based on pre-defined criteria, maximizing efficiency and reducing errors in decision-making.

- All vendor data is stored in one secure place, reducing security risks and helping manage compliance regulations more effectively.

The Perils of Manual Vendor Onboarding

Cumbersome, manual vendor onboarding processes not only take up valuable resources but are also laden with pitfalls. Without a streamlined onboarding process, you could be missing out on key data or documents—which can lead to delays or worse. You run the risk of not setting up supplier agreements correctly and not getting any insight at all into supplier performance. Plus, your suppliers may also get frustrated if there are long delays in the process.

Using a dedicated vendor onboarding platform has several advantages:

- Automated workflows guide users through the entire process from start to finish, reducing the time and resources needed for manual onboarding processes.

- Vendor onboarding platforms can provide a central source of data, keeping all of your vendors’ information in one place and making it easy to access what you need when you need it.

- Automation also allows supplier agreements and other documents to be created quickly and easily, reducing errors and delays in the process and improving accuracy.

- Finally, vendor onboarding platforms can provide visibility into supplier performance by tracking KPIs—allowing you to monitor supplier risk in real-time and make better decisions about how to manage them in the future.

Adopting an Automated Vendor Onboarding Process

When it comes to vendor onboarding, automation can come in very handy—especially for companies with a lot of suppliers. With automated vendor onboarding, you’ll be able to streamline the process more and eliminate paperwork and manual tasks.

Adopting an automated vendor onboarding process means:

- Your organization can develop a thorough vetting process to ensure all suppliers and vendors fit your criteria.

- You’ll be able to do real-time tracking of supplier/vendor compliance during the application and onboarding process.

- You’ll be able to store all documents in a secure online repository to increase visibility and traceability throughout the entire insourcing or outsourcing lifecycle.

- Automation can help speed up the overall application process, meaning fewer delays in the fulfillment of your orders.

- Your organization will benefit from an improved vendor management program that helps ensure your supply chain is free of risks associated with noncompliance.

SupplierGATEWAY’s Supplier Onboarding Platform helps streamline your vendor onboarding process by using custom workflows and automation, making new supplier onboarding easy for your company and your suppliers.

Applying Automated Solutions to Your Vendor Onboarding Process

Automated solutions have revolutionized the way businesses onboard new vendors, making onboarding faster, easier, and far more efficient.

Using an automated onboarding platform like SupplierGATEWAY’s can help you streamline your vendor onboarding process. With custom workflows and automated sequences, you can ensure that every step of the process is taken care of in a timely manner — from collecting relevant information from vendors to verifying important documents.

Plus, automated systems are incredibly secure and reliable — they don’t get tired or make mistakes, and they don’t require any manual intervention. That way, you can be confident that your data is always up-to-date and accurate — which is essential when managing a large number of vendors.

The best part? Automation makes it easy for both you and your vendors — simplifying the whole process so everyone benefits. With an automated system in place, you won’t need to worry about tedious paperwork or manual data entry — enabling your team to focus on more strategic tasks. Plus, giving your vendors an easier onboarding experience makes them more likely to stay with your company for the long haul. First impressions are important, after all!

Conclusion

So, there you have it — vendor onboarding doesn’t have to be an insurmountable task when you have the right platform in place. With SupplierGATEWAY’s comprehensive supplier onboarding platform, your organization can streamline the entire process. From automated document collection to advanced reporting and analytics, your supplier onboarding process can be simplified and optimized – saving you time and money.

By focusing on avoiding common mistakes and proactively responding to new issues and trends, you can ensure the success of your vendor onboarding process, keep suppliers happy and securely onboarded to your system, and help your business continue to grow and evolve.

Ready to make your supplier onboarding faster and easier than ever? Get in touch to request your demo.

What Is Supplier Diversity Data Enrichment?

If you’re a supplier diversity professional or a supply chain manager, you’re likely already familiar with the term “supplier diversity data enrichment.” But what is it exactly, and why do so many companies care about it?

Simply put, supplier diversity data enrichment) is the collecting and validating information and verifying businesses’ eligibility for programs offered by corporations, governments, and third-party organizations related to diversity initiatives. This data can include information like a business’s ownership type, certifications, size/revenue qualifications, contact information, etc.

The importance of accurate and up-to-date supplier diversity data cannot be overstated. It allows companies to effectively identify qualified suppliers that meet the criteria needed to benefit from their various programs and initiatives. That’s why understanding how to effectively enrich your supplier data is critical for supplier diversity professionals and supply chain managers. In this article, we’ll explore in greater detail what supplier diversity data enrichment is and how SupplierGATEWAY can help you ensure your data is always up-to-date.

What Is Supplier Diversity Data Enrichment?

Supplier diversity data enrichment is a process that helps organizations get a better understanding of their supplier base. It involves collecting, analyzing, and enriching information about the suppliers of goods and services that an organization works with. By analyzing this data, organizations can gain valuable insights into their suppliers’ backgrounds, capabilities, and potential synergies.

This process enables organizations to effectively identify and manage their diverse suppliers. It also allows them to better understand the differences between suppliers to make more informed decisions about who to work with. Furthermore, it helps organizations track the performance of their supplier base over time as well as ensure compliance with regulations and corporate policies.

Overall, supplier diversity data enrichment is an invaluable resource for organizations looking to get the most out of their supplier partnerships while ensuring they are meeting appropriate standards. With a thorough understanding of each supplier’s capabilities and background, businesses can ensure they are working with the right partners while cultivating a strong and diverse supplier base.

Benefits of Supplier Diversity Data Enrichment

Are you ready to take your supplier diversity program to the next level? Supplier diversity data enrichment is a powerful tool that can help you realize the full potential of your program.

Using data enrichment, you can improve the accuracy and completeness of the supplier information in your supply chain ecosystem. This can lead to improved visibility and analysis capabilities for existing suppliers and better decision-making when selecting new ones. You’ll also be able to leverage up-to-date insights on suppliers’ diversity profiles, certifications, records, and demographic trends over time.

Data enrichment also helps you streamline onboarding processes, which is essential for building strong relationships with suppliers. This will help ensure that all stakeholders have access to quality information quickly and accurately—and that you are leveraging all available resources to create a thriving and diverse supply chain network.

In short, supplier diversity data enrichment offers numerous tangible benefits for supply chain professionals looking for ways to optimize their supplier diversity program.

Steps to Performing a Supplier Diversity Analysis

You may have heard about supplier diversity data enrichment and wondered what it is and how to perform it. The process involves a few steps to ensure the supplier data you’re analyzing is accurate and up-to-date.

Step 1: Collect the Data

The first step in performing supplier diversity analysis is collecting demographic information from your suppliers. This includes race, ethnicity, gender, veteran status, ownership type, business size, and other relevant characteristics. This data is often hard to obtain. This is why third-party data enrichment benefits your supplier diversity program.

Step 2: Validate the Data

Once you have all this data, you’ll want to validate it. Validating your data means verifying that no records are fraudulent or inaccurate. During the validation process, missing or erroneous records will be flagged for removal or correction accordingly.

Step 3: Enrich the Data

The next step is enriching your supplier diversity data with more detailed demographic information about your suppliers. Data enrichment involves gathering more granular insights like how long a particular vendor has been in business, what industries they operate in, and any certifications or attestations a supplier may have about their diversity status.

By collecting and validating supplier diversity data, you can ensure that your analysis is comprehensive, accurate, and up-to-date — which helps you understand how diverse your supply chain is.

SupplierGATEWAY’s Supplier Diversity Platform gives you everything you need to run a successful supplier diversity program. From enriching diversity data to sourcing diverse suppliers, our platform enables your supplier diversity team in making impactful contributions to your bottom-line results.

Beyond Supplier Diversity Data Enrichment

SupplierGATEWAY’s Supplier Diversity Platform has the tools and capabilities to help you with supplier diversity data enrichment. The platform has all the features needed to run a successful supplier diversity program, and data enrichment is an important part of that.